Core Technologies

Vacuum Precision Casting Technology

Overview

Core Technologies

Vacuum Precision Casting Technology

Overview

As casting is implemented in a vacuum state under Vacuum Precision Casting, harmful gases like hydrogen, oxygen and nitrogen can be removed to enhance safety and quality of product. This not only prevents impurity and inclusion that are generated when molten metal meets air during welding process, but restricts casting defect caused by moist in the air as well. Also, even if alloying element is included, which is easily oxidized, this prevents potential loss of the alloying element and makes stable alloy composition. Given the precise and complicated nature of the process, it is suitable when mechanical work is not available. In particular, vacuum precision casting is critical for products with high melting point such as blade and vane. (As this type of products is operated under extremely hot temperature, vacuum precision casting technology is needed to enhance the mechanical strength.)

Among various types of castings, precision casting does not have shape limitation to freely produce complicated shapes or products that are not available for mechanical work. Also, it is cost-effective and possible for mass production.

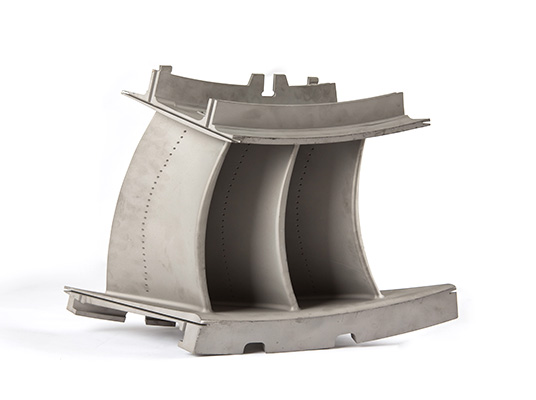

1st Vane Blade

1st Vane Blade 2nd Vane Blade

2nd Vane Blade EV Inner liner

EV Inner liner EV Outer liner

EV Outer liner SEV Inner liner

SEV Inner liner SEV Outer liner

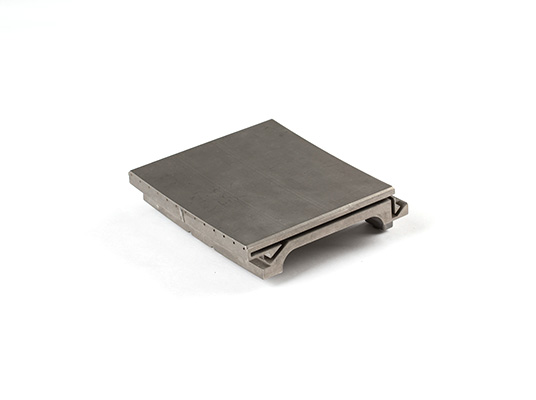

SEV Outer liner 2nd Shroud block

2nd Shroud block 3rd Shroud block

3rd Shroud block 3rd Vane

3rd Vane 1st Ring segment

1st Ring segment 2nd Ring segment

2nd Ring segment Bypass Elbow

Bypass Elbow