Core Technologies

Thermal Barrier Coating Technology

Overview

Core Technologies

Thermal Barrier Coating Technology

Overview

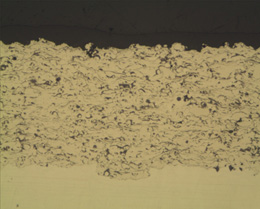

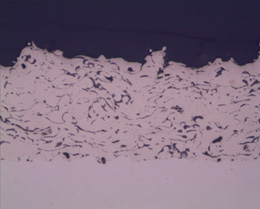

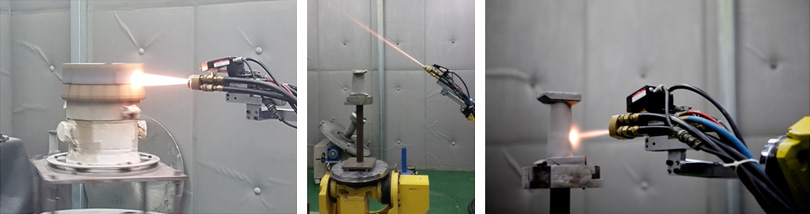

TBC is applied to aircraft, GT engine and other parts enduring high temperature. The coating consists of ceramic top coat with low thermal conductivity and bond coat that makes top coating more adhesive. By setting up adequate porosity on top coat, it develops low thermal conductivity and high deformation resistance, cooling the material surface down 100 ~ 170℃ from the flame temperature. This helps overcome the limitation of turbine components.

| CLASS – B | CLASS – C | Super B | Super C |

|---|---|---|---|

| ~ 0.40mm | ~ 0.60mm | ~ 1.00mm | ~ 2.00mm |

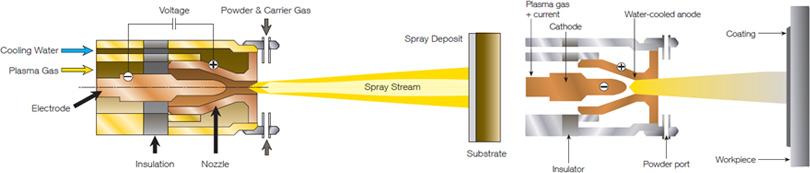

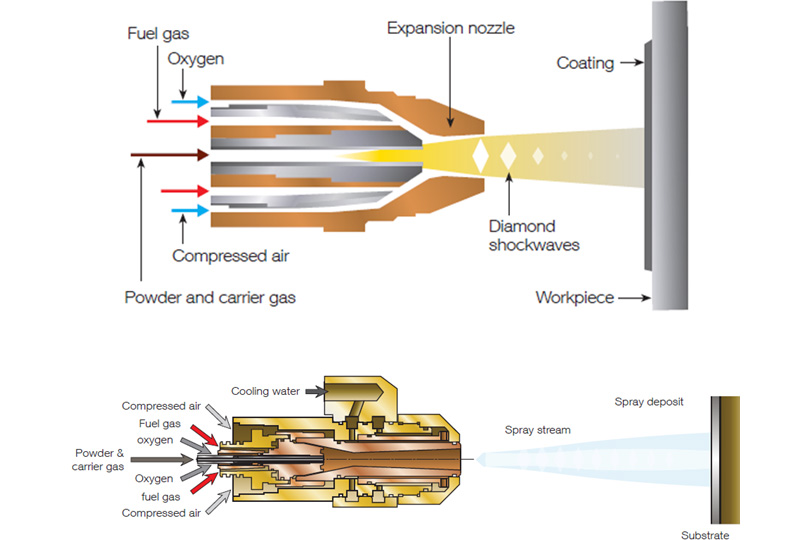

Between electrode (anode, or positive pole) and nozzle (cathode, or negative pole), high-frequency arc is generated. And the gas flowing between electrode and nozzle gets ionized to develop several-centimeter thick plasma plume with temperature reaching 16,000 degrees Fahrenheit. Meantime, powder is injected into the plasma plume from the outside of gun nozzle and melted there and then quickly sprayed onto the product surface by the pressure of gas to form coating layer.

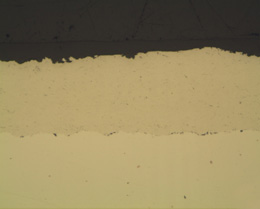

TBC Coating(2mm)

TBC Coating(2mm) CoNiCrAlY Coating

CoNiCrAlY Coating NiCrAlY Coating

NiCrAlY Coating| Product size | Inner Diameter Coating | I.D = Min. Ö 280mm / L = Max. 2,000mm |

|---|---|---|

| Outer Diameter Coating | O.D = Max. Ö 2,500mm / L=Max. 4,000mm | |

| Applied coating material | Cr3C2-NiCr, MCrAlY, ZrO2-Y2O3, Low K | |

As the mixture of gaseous fuel or liquid fuel and oxygen enters combustion chamber, it ignites consecutively. The ignition is further accelerated when powder moves into the flame. While the hot gas and powdered flame are sprayed onto the product surface, this power melts within the flame to coat the material surface.

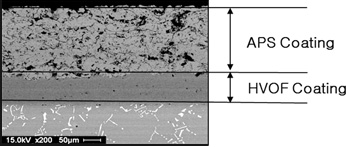

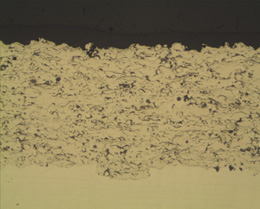

CoNiCrAlY - HVOF

CoNiCrAlY - HVOF CoNiCrAlY - APS

CoNiCrAlY - APS| Product size | Inner Diameter Coating | I.D = Min. Ö 280mm / L=Max. 1,200mm |

|---|---|---|

| Outer Diameter Coating | O.D = Max Ö 3,000mm / L=Max. 4,000mm | |

| Applied coating material | Cr3C2-NiCr, MCrAlY | |